Operation SAFE (Self-regulating Application & Flight Efficiency), developed in 1981, was designed to clearly demonstrate that ag aviation recognizes its responsibility to minimize the potential for adverse health and environmental effects of agricultural chemical application.

Objective

Connect pilots and operators with trained and vetted professional analysts, providing not only education, but the opportunity to measure and assess application efficacy and mitigate drift.

Means to Achieve the Objective

Operation SAFE consists of a comprehensive program of education and professional analysis of application. The backbone of Operation SAFE is the Professional Application Analysis Clinic (Fly-In). Participating at a Fly-In involves the standardized measurement of collected samples from test passes made by an aircraft. These measurements provide relative deposition and (for liquid applications) droplet size. NAAREF-recognized Operation SAFE Analysts, including USDA and University scientists, industry experts and operators are trained to interpret these measurements and provide the pilot or operator with recommendations for equipment adjustment (if needed) and projected in-field performance.

Preparing for a Fly-In

Plan to arrive at the fly-in with a fully cleaned aircraft and spray system. Flow check all nozzles and fix any leaks. Plan to bring spare spray system parts (nozzles, check valves, J-tubes, etc.) in case they are needed. It is also advised to bring 50-100 gallons of water, if able.

Be prepared to provide the details of your aircraft and spray system configuration. It is encouraged for you to pre-fill the Operation SAFE Aircraft Information Form and bring it with you.

Attending a Fly-In

When you arrive, check in with the analysis center to receive a safety and protocol briefing and fill out your Aircraft Information Form. You will be provided with tracer dye to mix in the hopper, and be informed of the order in which attending aircraft will be tested.

Making the Test Passes

When it is your turn to test, takeoff and be vigilant of traffic. In an area downwind of the flight line (test-area), purge your booms by spraying until dye is visibly coming out of the most outboard nozzles.

When signaled by the ground crew (via radio or flags), approach the flight line by aligning your flight path with the marked centerline (typically 3 white bags on posts). Descend to your desired application height and turn on the spray system 300-400 feet before the flight line. Maintain level flight, minimizing control movements until you are at least 300 feet past the flight line. Then, turn off the spray system and smoothly climb back into a holding pattern.

The ground crew will signal you when they are ready for another pass. A total of 3 passes will typically be made before you land.

Analyzing the Results

Once back on the ground, await the processing of your collected data in the analysis center. The Operation SAFE Analyst will review your processed results and discuss them with you. A report will be provided, showing both a pattern analysis and a droplet spectrum analysis. The pattern analysis shows deposition across the swath as well as effective swath width and projected in-field uniformity. The droplet spectrum analysis shows in-swath spray quality via computed droplet spectrum categories (Medium, Coarse, etc.).

If you and the analyst agree on making adjustments, or if you desire to test other rates/configurations, another set of test passes may be made.

Operation SAFE is administered by NAAREF, who recommends having your aircraft evaluated every 2 years or after major changes are made to the application system. Some key benefits from participating are:

- Measurement and characterization of application pattern

- Determination of optimum effective swath width

- Documentation of expected application performance

Any licensed operator or aerial applicator is encouraged to participate in Operation SAFE. As an added benefit for participating NAAA members, an Operation SAFE Emblem (sticker to affix to aircraft) may be obtained to show others your commitment to making an accurate application.

In addition to several consultants, many State and Regional Agricultural Aviation Associations regularly host Operation SAFE Clinics. There are also options for conducting your own pattern testing and consulting with a NAAREF-recognized Analyst. See Analysts below.

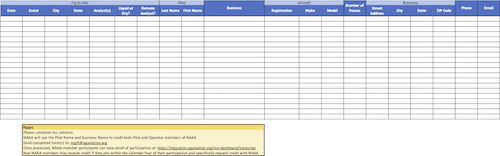

Analysts submit participant logs from Operation SAFE to NAAA. If you participate as an NAAA member, you can obtain a Participation Letter to provide your customers, insurer, etc. It is a PDF with a unique ID showing the date, location, business and aircraft registration(s) for participating aircraft. Letters for 2021-Present can be found in your Transcript in the NAAA Education center (see link below). Letters for 2020 and earlier are available upon request.

NAAREF recognizes Operation SAFE Analysts as trained professionals in conducting aircraft pattern testing. They are not only proficient with operating the needed equipment to conduct the fly-in, but also experienced in interpreting and analyzing the collected data to formulate recommendations. It is the Analyst who consults with the applicator and ultimately verifies their participation in Operation SAFE to NAAA.

Analysts – United States

| Analyst | Company | State | Renewal Due | |

|---|---|---|---|---|

| Craig Bair | Bair Aviation Inc. | SD | bairaviation@gmail.com | 2027 |

| Scott Bretthauer | NAAA | IL | sbrethauer@agaviation.org | 2025 |

| Kim Pope-Brown | Louisiana Ag Aviation Association | LA | popekim36@gmail.com | 2025 |

| Robert Ching | DropFlight | MI | robert@dropflightag.com | 2026 |

| Alan Corr | Agri-Spray Consulting LLC | NE | alan@agrisprayconsulting.com | 2026 |

| Carson Corr | Agri-Spray Consulting LLC | NE | carson@agrisprayconsulting.com | 2026 |

| Corey Fransen | JBI Helicopter Services | NH | corey.fransen@jbihelicopters.com | 2025 |

| Brad Fritz | USDA-ARS | TX | brad.fritz@usda.gov | 2026 |

| Dennis Gardisser | WRK of Arkansas LLC | AR | dgardisser@icloud.com | 2026 |

| John Garr II | GarrCo Products Inc | IN | mrfoam@garrco.com | 2025 |

| Matt Gill | NAAA | IL | mgill@agaviation.org | 2026 |

| John Hill | – | MI | jsjjj@charter.net | 2026 |

| Matt Hovdenes | Right Way Ag | ND | rightwayag@outlook.com | 2026 |

| Madison Krahl | Transland LLD | TX | mkrahl@translandllc.com | 2025 |

| Dan Martin | USDA-ARS | TX | daniel.martin@ars.usda.gov | 2025 |

| Ruben Nieto | Transland LLC | TX | rnieto@translandllc.com | 2025 |

| Randy Price | Louisiana State University | LA | rprice@agcenter.lsu.edu | 2026 |

| Brad Ruden | Agtegra Cooperative | SD | brad.ruden@agtegra.com | 2027 |

| Tim Shamblin | Aero Applications Inc. | ID | timshamblin@gmail.com | 2027 |

| Eric Vest | WRK of Arkansas LLC | AR | vestro91@yahoo.com | 2026 |

| Jill Vest | WRK of Arkansas LLC | AR | rnqtee75@yahoo.com | 2025 |

| Destiny West | Perfect Flight | CO | destinywest045@gmail.com | 2025 |

| Richard Whitney | WRK of Oklahoma | OK | whitney3451@att.net | 2026 |

| Jim Wilson | South Dakota State University | SD | jrwltd@itctel.com | 2027 |

| Anthonie York | Air Tractor | TX | ayork@airtractor.com | 2026 |

Analysts – International

| Analyst | Company | Country | Renewal Due | |

|---|---|---|---|---|

| Michael Bannerman | Forest Patrol | Canada | bannerman.michael@jdirving.com | 2025 |

| Josue Barerra | Agrocentro | Guatemala | josue.barrera@agrocentro.com | 2026 |

| Andrew Brown | Forest Patrol | Canada | andrewbrown@live.ca | 2025 |

| Henrique Campos | Sao Paulo State University | Brazil | henrique@sabri.com.br | 2026 |

| John Dornian | Skyway Aviation | Canada | jdornian@hotmail.com | 2025 |

| Walter Dyck | Jonair (1988) Ltd. | Canada | waldyck@gmail.com | 2025 |

| Richard Friesen | Western Canadian Aerial Ltd. | Canada | exiraaero@outlook.com | 2027 |

| David Frisch | Jonair Ltd. | Canada | dave@jonair.com | 2025 |

| Rudy Gerzen | Southeast Air | Canada | rgerzen478@gmail.com | 2025 |

| Rylan Hiebert | Portage Aircraft Maintenance | Canada | fastford150@hotmail.com | 2025 |

| Paul Hubbard | Granular Products | Australia | paul@granularproducts.com | 2025 |

| Reeve Hubbard | Drone Agriculture | Australia | reeve@droneagriculture.com.au | 2025 |

| Johan Jancen | Western Canadian Aerial Ltd. | Canada | johaniliana1995@gmail.com | 2027 |

| Scott Kiansky | Southeast Air | Canada | kianskys@gmail.com | 2025 |

| Shaun Kinniburgh | Kinniburgh Spray Service Ltd | Canada | shaun@kinniburghspray.com | 2027 |

| Chris Lambert | Western Canadian Aerial Ltd. | Canada | chris@wcaerial.com | 2027 |

| Corey Lange | Wetaskiwin Aerial Applicators Ltd. | Canada | waacorey@gmail.com | 2026 |

| John Lepp | Rivers Airspray | Canada | johnleppfarms@gmail.com | 2025 |

| Chad Moffat | Specialized Spray Systems | Canada | specializedspray@gmail.com | 2026 |

| James Pottage | Provincial Airways | Canada | james@provincialairways.net | 2027 |

| Ken Proden | Jonair (1988) Ltd. | Canada | kennyproden@gmail.com | 2025 |

| Clayton Rempel | Clayton Air Service Ltd. | Canada | claytonairsk@gmail.com | 2026 |

| Lowell Ritchey | Fairfield Services Ltd. | Canada | lritchey@telus.net | 2028 |

| David Roy | Western Canadian Aerial Ltd. | Canada | droy1981@hotmail.com | 2027 |

| Brett Rubbert | Bretts A Service | Canada | brubbert@hotmail.com | 2025 |

| Markus Seitter | Western Canadian Aerial Ltd. | Canada | chiefpilot@wcaerial.com | 2027 |

| Tyler Thall | Hanley Heli | Canada | tyler@hanleyheliservice.ca | 2025 |

| Ian Torrie | Arty’s Air | Canada | maintenance@artysair.com | 2027 |

| Nicolas Verrault | SPOFIM | Canada | n.verreault@sopfim.qc.ca | 2025 |

| Reiss Wiklund | Jonair Ltd. | Canada | reiss@jonair.com | 2025 |

| Leonel Yaeggy | Duwest | Guatemala | leonel.yaeggy@duwest.com | 2025 |

| Ian Yaholnitsky | Miccar Aerial | Canada | ian@miccaraerial.com | 2025 |

To aid the Analyst in conducting the fly-in, NAAREF recognizes Operation SAFE Technicians as individuals proficient with operating the needed equipment to conduct the fly-in. Technicians may assist in all aspects of the fly-in, except for making aircraft setup recommendations.

Technicians – United States

| Analyst | Company | State | Renewal Due | |

|---|---|---|---|---|

| Gwen Corr | Agri-Spray Consulting LLC | NE | gwen@agrisprayconslting.com | 2025 |

| Megan Corr | Agri-Spray Consulting LLC | NE | megan@agrisprayconsulting.com | 2026 |

Technicians – International

| Analyst | Company | Country | Renewal Due | |

|---|---|---|---|---|

| Dan Ballard | Western Canadian Aerial Ltd. | Canada | daniel_ballard8@hotmail.com | 2027 |

| Corey Froese | Western Canadian Aerial Ltd. | Canada | coreyfroese.1995@yahoo.com | 2027 |

| Dean Kozak | Western Canadian Aerial Ltd. | Canada | deankozak@gmail.com | 2027 |

| Justin McKenzie | Western Canadian Aerial Ltd. | Canada | justin@wcaerial.com | 2027 |

| Colin Paul | Western Canadian Aerial Ltd. | Canada | colin@wcaerial.com | 2027 |

| Lucas Vandercamp | Western Canadian Aerial Ltd. | Canada | lucasvdk152@gmail.com | 2027 |

| Nick Zoppa | Western Canadian Aerial Ltd. | Canada | nick@wcaerial.com | 2027 |

NAAREF approves Analysts and Technicians for a period of 3 calendar years. The requirements for initial approval and renewal are listed below. While not explicitly listed as a requirement, it is also expected that Analysts and Technicians will perform their duties with great professionalism as ambassadors of NAAREF. It is also expected that they will maintain currency in this field through literature and professional interaction. NAAA Membership is required.

Initial Approval

NAAREF may approve qualified NAAA members to become Operation SAFE Analysts or Technicians based on recommendation by either (1) or (2) below:

- Attend a NAAREF-approved Analyst/Technician training course, where, upon successful completion, a recommendation will be submitted to NAAREF.

- An existing Analyst may recommend (in writing) individuals that possess the knowledge and skills to serve as an Analyst or Technician to NAAREF.

Initial approval will end on the 31st day of December of the third year from the date of initial approval and may be renewed every three years by meeting the renewal requirements.

Renewal

Analysts and Technicians may renew their approval by providing written documentation to NAAREF of completion of (1) and (2) during the 3 year period following your most recent approval/renewal, but before the expiration of that approval/renewal:

- Certify attendance at a minimum of three of any combination of the following professional development meetings:

- NAAA Conventions

- PAASS Programs

- State/Regional AAA Conventions

- ASAE/ASTM Pesticide Application Meetings

- Conduct or materially assist in conducting at least two fly-ins, and make at least 5 calibrations

- Conduct or materially assist in conducting at least two fly-ins, and make at least 5 calibrations

An iPhone/iPad app that allows extremely fast scanning and analysis of water-sensitive spray cards, all on your Apple mobile devices. This tool, created in part by an aerial applicator, is targeted specifically for aerial applicators to use in assessing spray pattern uniformity, effective swath width and droplet size across the swath.

Portable onsite swath sampling and processing system that analyzes the full spray swath. Using inexpensive calculator paper rolls and dye as a collector, The Swath Gobbler™ system quickly and precisely reads spray data and provides actionable outputs. Swath Gobbler™ gives you the research-quality data you need to be the best in your field.

Desktop (MacOS/Windows) software to conduct Operation SAFE Fly-Ins. For traditional string/card combination or standalone card-only testing. Designed to be used by Applicators and Operation SAFE Analysts alike.

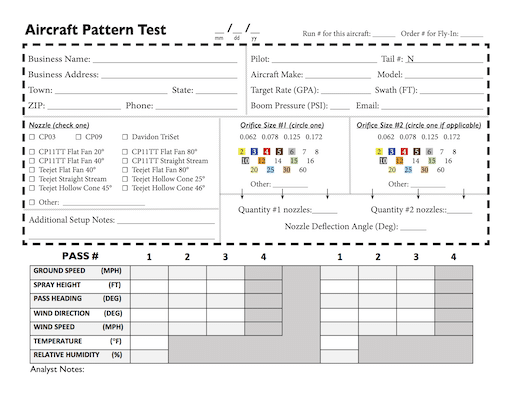

Fillable SAFE Aircraft Information Form

This form may be printed and filled out prior to attending an Operation SAFE Fly-In. This will ensure expedient and accurate input and processing of your aircraft data. This form may also be utilized by individuals conducting their own spray pattern testing and working with a remote analyst for the same purpose.

Remote-Analyst Fly-In Protocol

A generalized guide for aerial applicators to conduct their own spray pattern testing without an on-site Operation SAFE Analyst. Collected test samples can be processed by an applicator or mailed to an Analyst for processing.